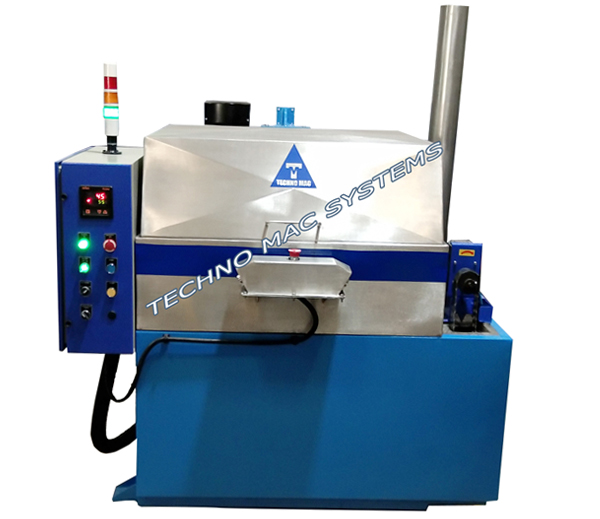

Rotary Table Washers / Washing Machines Manufacturer, Supplier, Exporter

We are Manufacturer, Supplier, Exporter Of Rotary Table Washers, Rotary Table Washing Machines and our set up is situated in Pune, Maharashtra, India.

The rotary type component cleaning machine has been developed to provide fast and efficient cleaning of manufactured components. Components would be loaded on basket, which is rotated by a AC motor and gearbox at constant speed regardless of the load. During the rotation, the solution (water along with chemical) from the tank is pumped with the help of centrifugal pump to wash chamber through inline filter onto the components to attain higher degree of cleaning results. From Wash chamber it drains back to the tank via a basket filter. Spray pressure indicator (Glycerin filled pressure gauge) is provided to monitor the line pressure. Low water level indication and Digital temperature indicator cum controller is provided on the control panel.

The machine is provided with automatic opening & closing of canopy. The entire tank, body and body cover will be of stainless steel.

Exhaust Ducting is supplied along with machine to take out the water vapors outside the machine.

Key Features:

- Economical operational costs.

- Developed for efficient, rapid, and cost-effective cleaning.

- Suitable for diverse component cleaning within a single machine.

- Features a multi-tier filtration system with a belt-type oil skimmer for removing floating oil.

- Constructed from stainless steel for enduring reliability.

- Portable design facilitates easy relocation.

- Customizable to meet specific cleaning requirements.

- Space-saving and economical, offering high cleanliness standards at low cost.

- Available with basket sizes ranging from 600mm to 1500mm in diameter.

- Developed for fast and efficient cleaning of manufactured components.

- Suitable for parts with simple geometry; can handle batches of small parts in a basket or individual large parts on fixtures.

- Control of the minimum liquid level in the tank to protect the pump and resistance.

- Tanks accessible from the outside.

- The rotary table washing cabins operate through a sequential "rotary table" system, completing six distinct treatment stages:

- Loading parts manually or automatically.

- Washing and degreasing the parts.

- Vapor extraction.

- Blowing with compressed air.

- Drying with hot air.

- Unloading the treated parts.